NEW TRENDS

INTERIOR DESIGN

BESTSELLERS

MODERN CHAIRS

BESTSELLERS

MODERN CHAIRS

NEW TRENDS

INTERIOR DESIGN

Company Profile

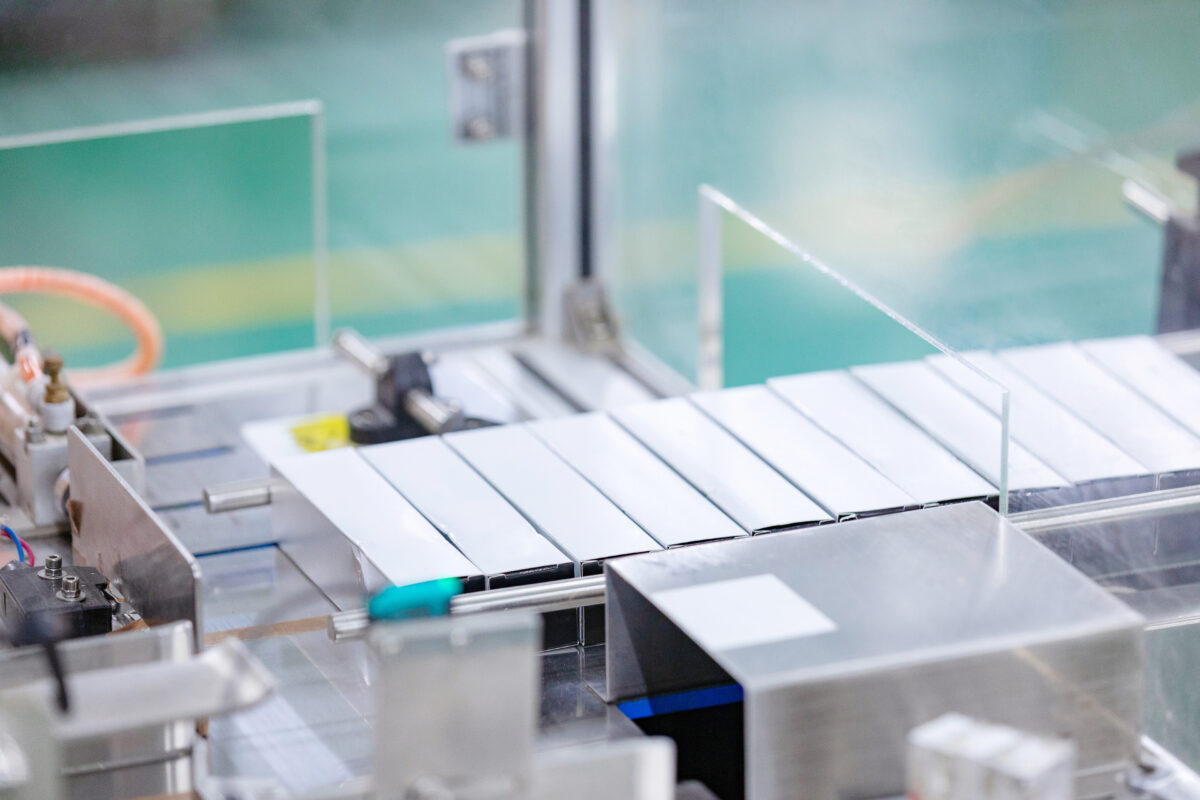

Universal Marking is a leading innovator in the coding and marking industry, specializing in advanced laser marking machines designed to deliver precision, efficiency, and sustainability for modern manufacturing and packaging needs. With years of technical expertise and a customer-centric approach, we empower businesses worldwide to achieve flawless product traceability, branding, and regulatory compliance.

Core Expertise As pioneers in laser marking technology, we develop state-of-the-art systems that create permanent, high-resolution markings on diverse substrates—including metals, plastics, glass, ceramics, and organic materials. Our solutions eliminate the need for consumables like inks or solvents, offering an eco-friendly alternative to traditional contact-based or inkjet coding methods. Vision Driven by innovation, we strive to redefine the future of industrial coding by merging laser precision with tech-driven automation, helping clients thrive in an era of smart manufacturing and stringent sustainability mandates.

Our Services

Comprehensive Service Portfolio At Universla Marking we go beyond delivering cutting-edge laser coding machines—we provide 360° support to ensure seamless integration, optimal performance, and continuous innovation for your coding and marking operations. Our services are designed to empower your team, minimize downtime, and future-proof your production processes

1. Pre-Sale Consultation & Customization Needs Assessment: Our experts conduct in-depth analyses of your production environment, substrate types, throughput requirements, and compliance standards. Sample Testing: Free material trials to demonstrate marking quality, adhesion, and readability on your specific products. Solution Design: Tailored hardware/software configurations (e.g., fiber, CO2, or UV lasers) matched to your line speed, space constraints, and budget.

2. Installation & Integration On-Site Deployment: Certified engineers handle machine setup, calibration, and integration with existing production lines (e.g., conveyors, vision systems, PLCs). Line Optimization: Real-time adjustments to ensure synchronization with high-speed workflows and minimal disruption. Compliance Assurance: Validation support for industry-specific standards (e.g., ISO, GMP, FDA 21 CFR Part 11).

3. Training & Knowledge Transfer Operator Training: Hands-on sessions covering machine operation, routine maintenance, and safety protocols. Software Mastery: Advanced workshops for IT/engineering teams on coding logic, variable data integration, and user permissions. 24/7 Digital Resources: Access to video tutorials, troubleshooting guides, and a centralized knowledge base.

4. Post-Sale Support Dedicated Helpdesk: Multilingual technical support via phone, email, or live chat with a guaranteed 4-hour response time. Preventive Maintenance: Scheduled inspections, lens cleaning, and component diagnostics to extend equipment lifespan. Spare Parts Network: Global inventory of genuine components for rapid replacements, backed by traceable warranties.

5. Upgrades & Future-Proofing Software Updates: Regular enhancements for security patches, new marking templates, and ERP/MES compatibility. Retrofitting Services: Cost-effective upgrades to add new functionalities (e.g., AI-powered defect detection, cloud connectivity). Leasing Options: Flexible financing models for technology refresh cycles.

6. Sustainability Services Energy Audits: Recommendations to reduce power consumption without compromising output. Recycling Programs: Eco-friendly disposal/recycling of retired machines and components. Carbon Reporting: Tools to quantify and showcase your reduced environmental footprint.

7. Industry-Specific Solutions Pharma & Medical: Serialization compliance, audit trails, and aggregation support for DSCSA, EU FMD, etc. Food & Beverage: Hygienic design validation and CIP (Clean-in-Place) compatibility. Automotive: Permanent VIN marking and traceability systems for IATF 16949 compliance. .

Why Partner With Us?

Proactive Problem Solving: Predictive analytics to address issues before they impact production. Global Reach, Local Presence: Service hubs globally ensure rapid on-ground assistance. Lifetime Partnership: Continuous innovation sharing through webinars, whitepapers, and R&D collaborations.